📍 Project Overview

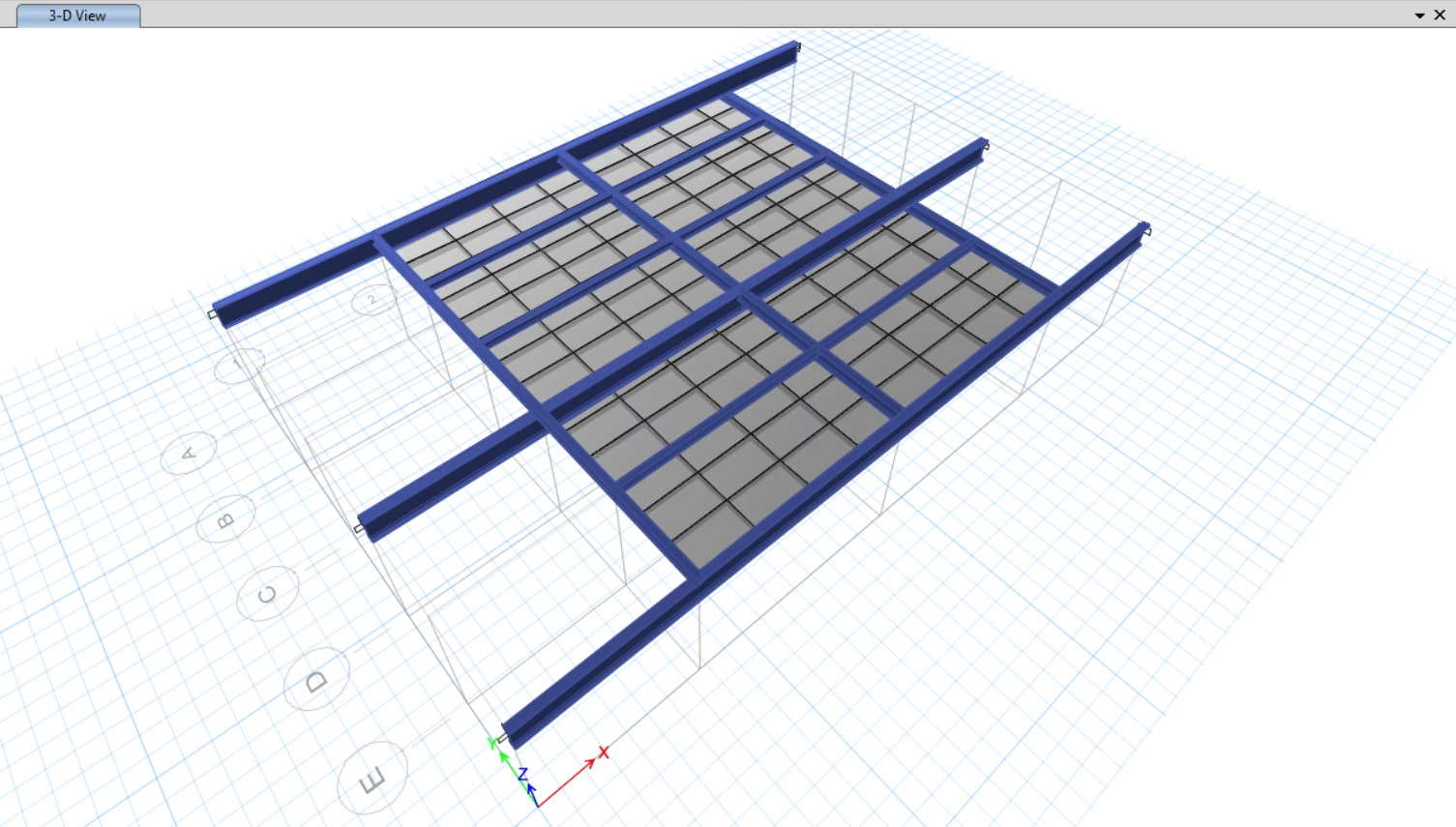

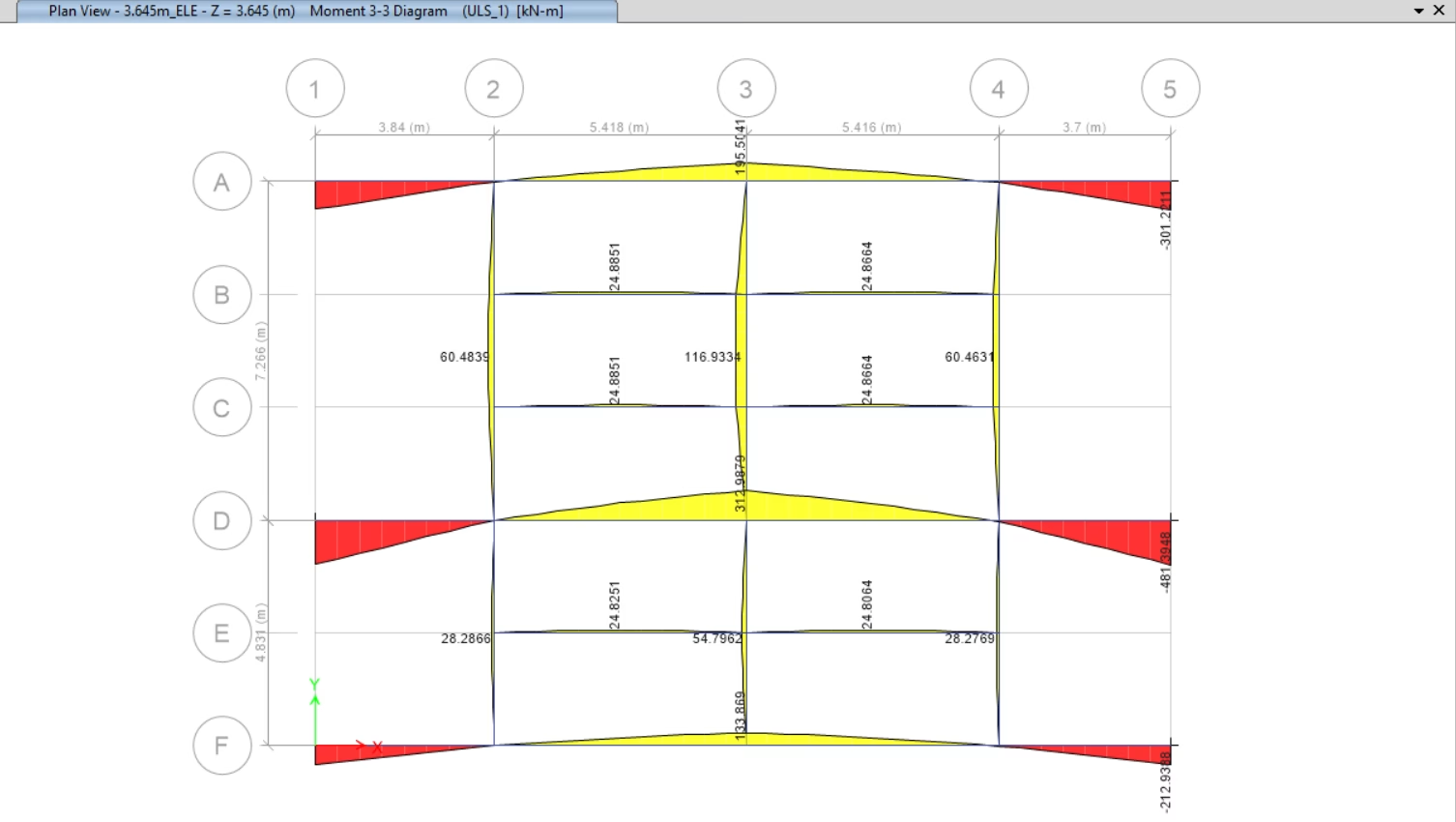

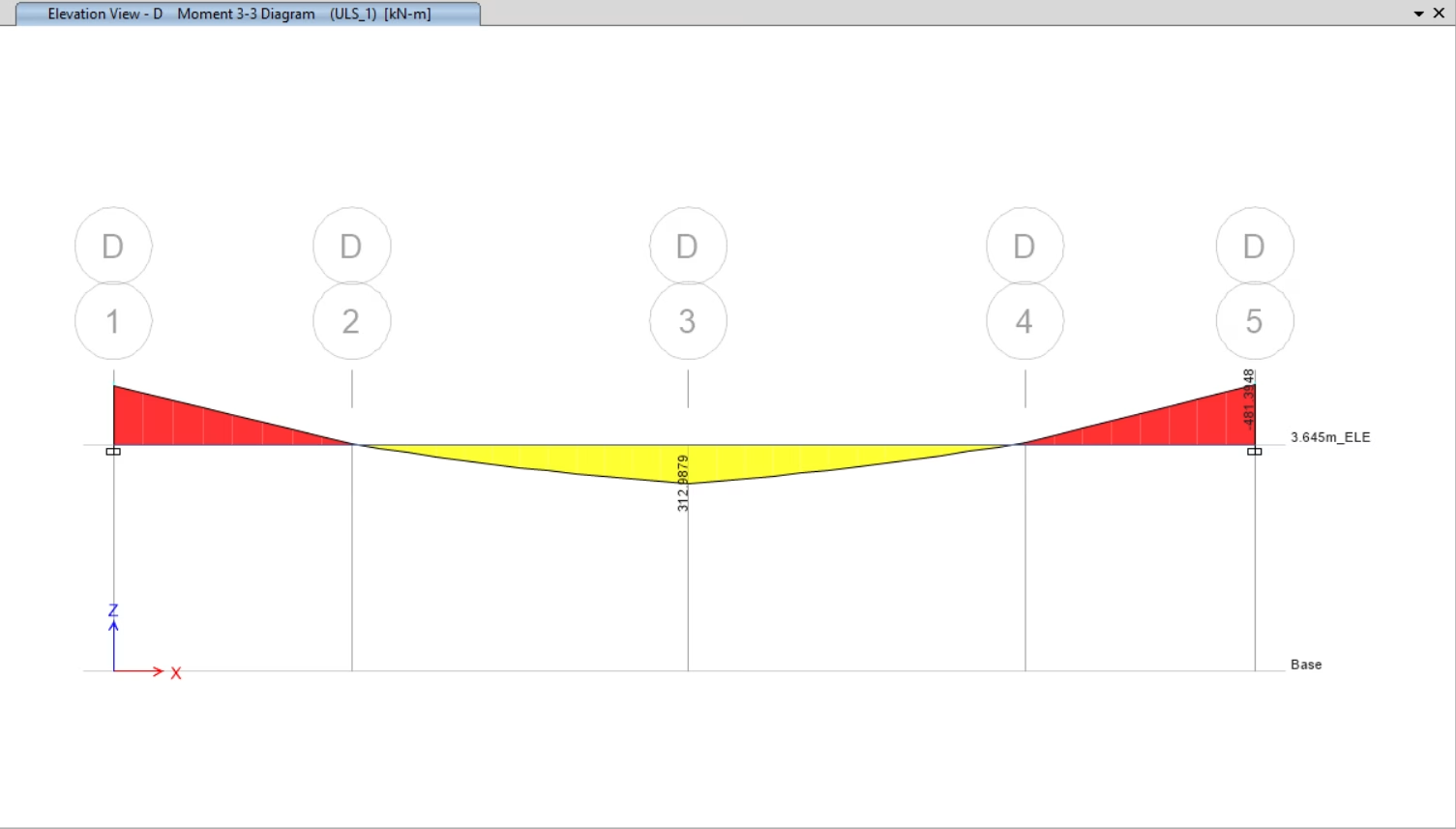

At Paddick Engineering, we continue to deliver high-performance structural solutions that balance durability with practical constructability. This featured project showcases a steel floor framing system designed using flush end plate bolted connections and double angle shear plate connections, optimised to enhance strength, modularity, and ease of installation across a commercial floor span.

🧩 Connection Detailing: Designed for Performance

Detailing precision was a key priority in this system. The connection types used provide both strength and constructability without compromising on efficiency.

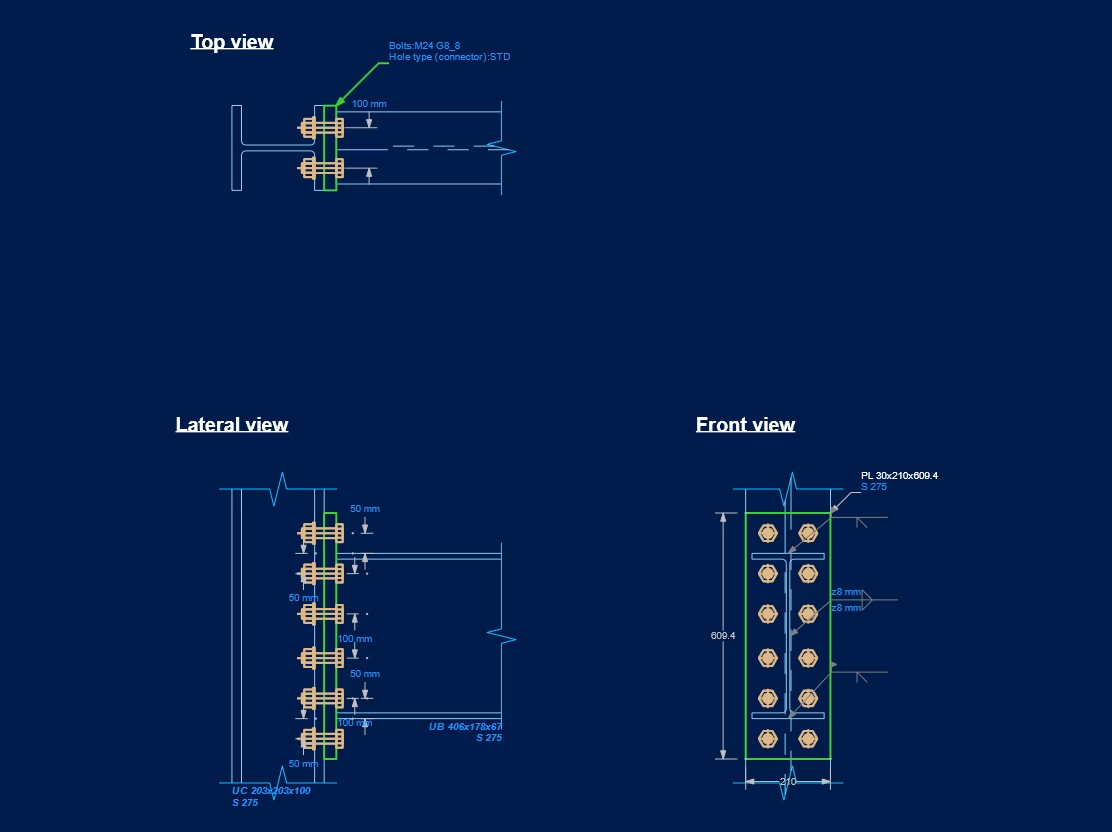

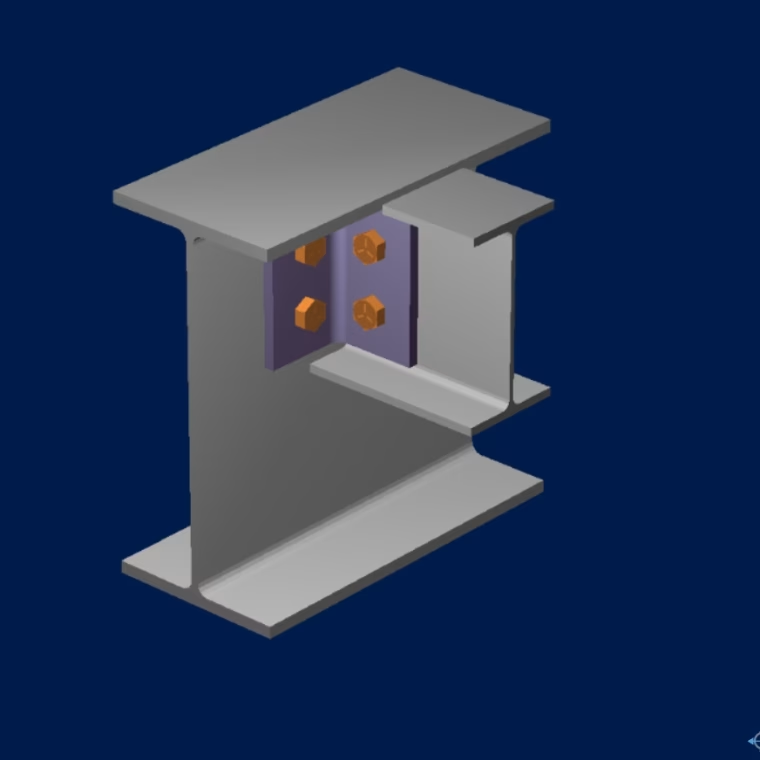

🔧 Flush End Plate Bolted Connection

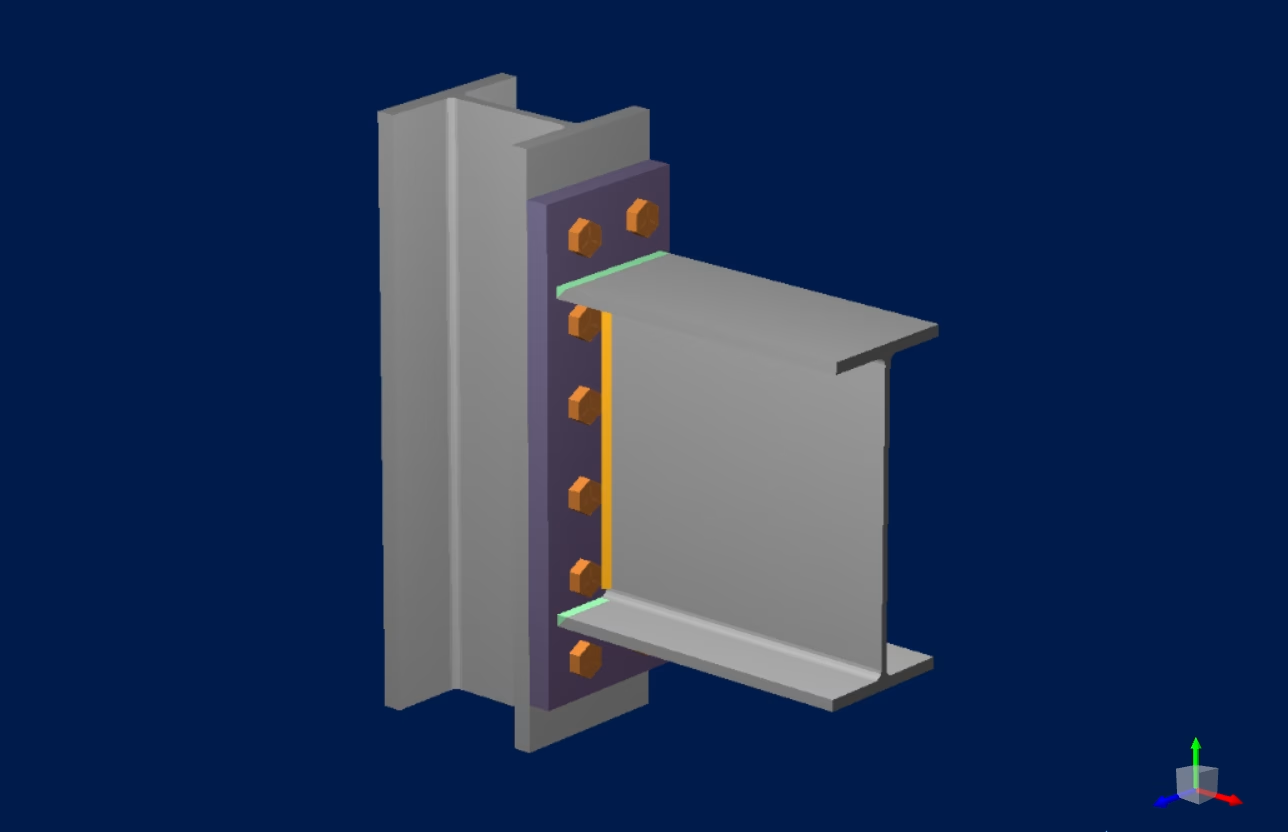

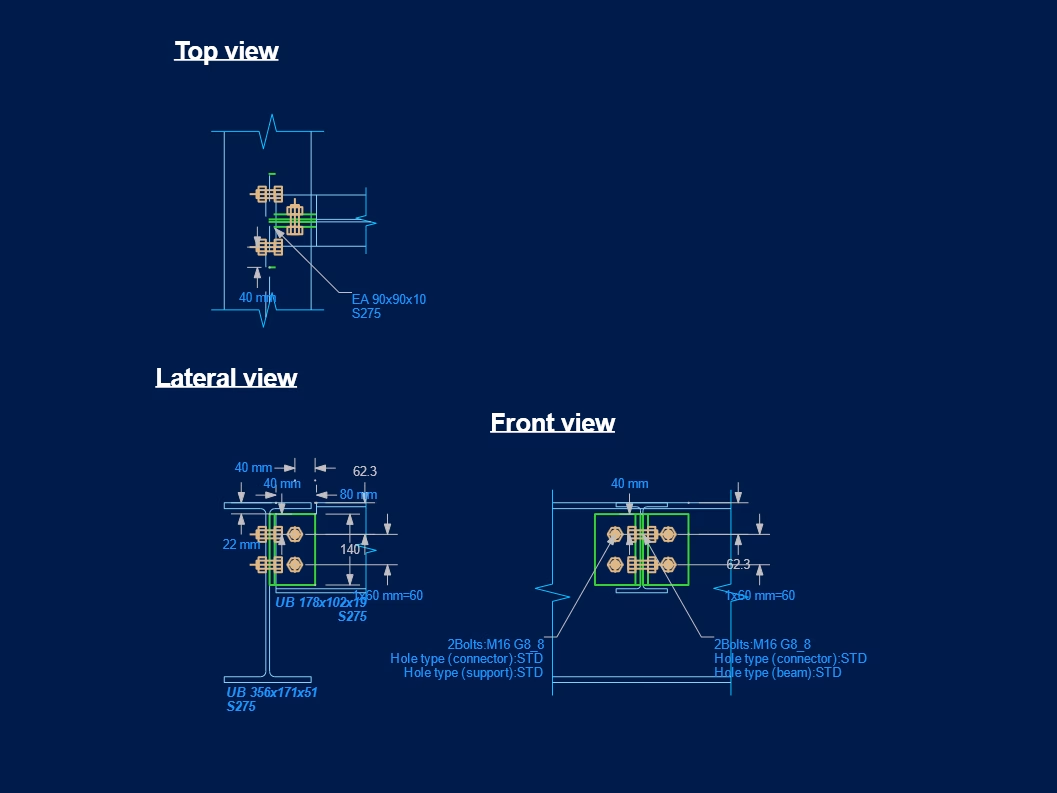

🔧 Double Angle Shear Plate Connection

Comprehensive detailing was prepared, including:

✅ 3D isometric modeling for visual clarity

✅ Dimensional drawings (front, top, and side views)

✅ Complete bolt layouts and plate geometry for fabrication and on-site guidance

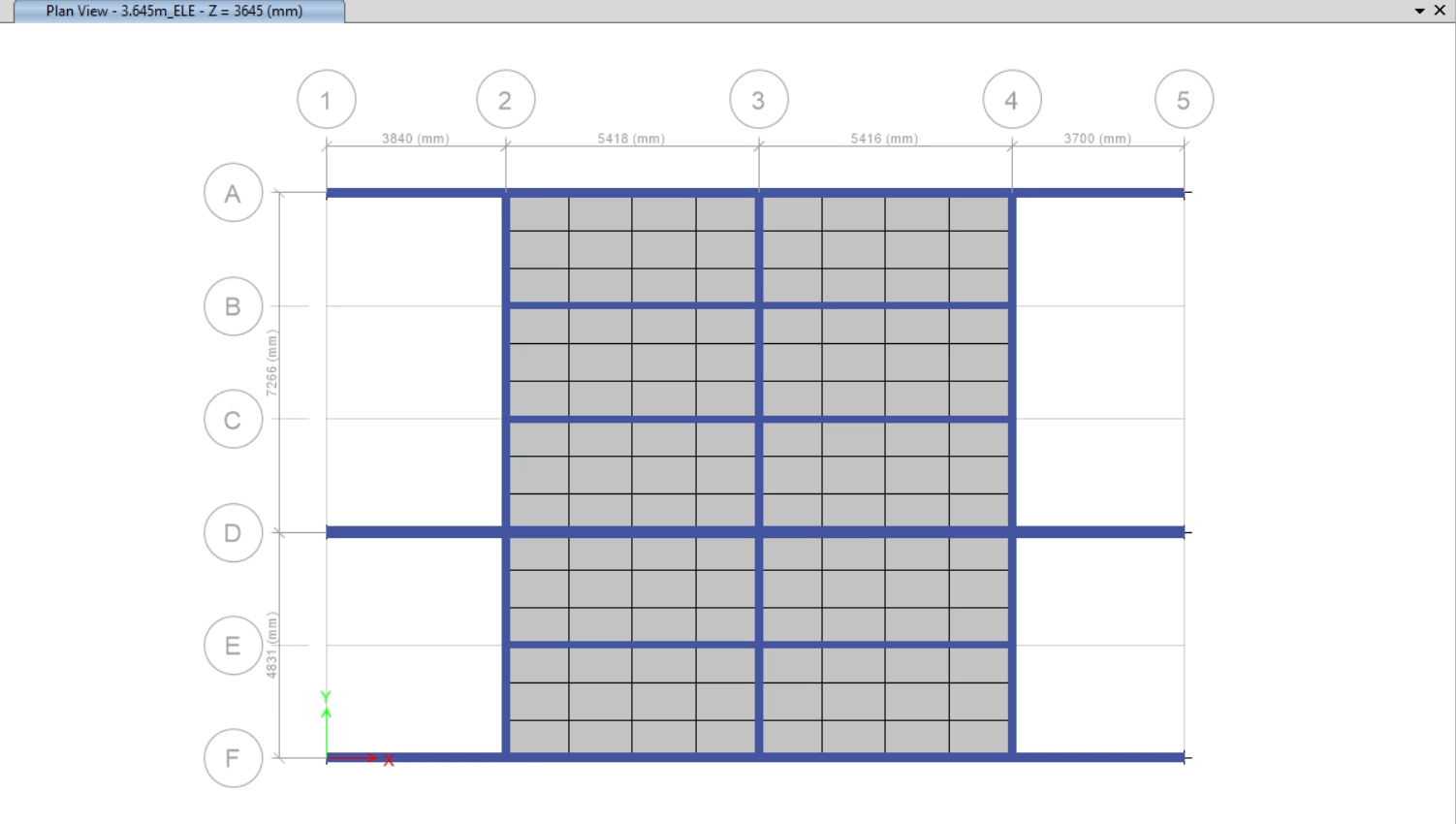

🧱 Floor Framing Layout: Built to Carry & Coordinate

The floor layout consists of a structural steel grid that efficiently distributes loads while allowing for coordinated service integration. The modular system was developed with construction speed and flexibility in mind.

Key Features:

Grid arrangement of primary and secondary beams

Modular layout compatible with slab panel systems

Coordination-ready for MEP installations

Developed using BIM tools to ensure dimensional accuracy and fabrication precision

💡 Why This Matters

Our approach supports:

✅ Efficient load transfer in both directions

✅ Rapid and repeatable on-site assembly

✅ Code-compliant design to Eurocode standards

✅ Reduced construction timelines and coordination overhead

At Paddick Engineering, we’re passionate about turning detailed design into buildable reality. From robust structural layouts to fully integrated BIM models, we deliver engineering that performs and builds better.

📩 Interested in innovative steel detailing or BIM driven engineering support? Let’s talk.